SURFACE TREATMENT

We perform various types of surface treatment on our products at our own surface treatment plants. Priming, varnishing, painting and hot dip galvanizing is carried out by Weland AB or one of our subsidiaries.

Varnishing

In our modern painting facilities, the work is done in primed or varnished versions. Thanks to our large premises, we can handle bulky objects measuring up to 10 x 10 meters for both sand-blasting and painting. Top-coating can be done in all shades of the RAL scale.

Powder painting, which is performed by Weland AB, provides an excellent result and is well suited for products used indoors. Wet painting, which is carried out by our subsidiary Weland Welded Components AB, is a durable surface treatment that is particularly suitable for products that are to be used outdoors but cannot be hot-dip galvanized.

Hot dip galvanization

Hot-dip galvanization of steel provides very effective rust protection, and is an excellent alternative for steel products used outdoors. A hot-dip galvanized product can also be painted.

The steel product that is to be hot-dip galvanized is immersed in a zinc bath with molten zinc. A reaction then takes place in the contact surface between steel and liquid zinc, and an iron/zinc alloy is formed. This means that the zinc layer cannot flake off or rust from the inside. The hot dip galvanizing is performed by our subsidiary Zinken Weland AB in Ulricehamn.

For wet painting, Weland Welded Components AB works using Polane paint, which is characterised by the minimal amount of paint required. This makes it an environmentally sustainable alternative, whilst the low amount of paint required means that it dries quickly. Wet painting using Polane is the perfect choice for products that are to be used outdoors but which, for various reasons, cannot be hot dip galvanized.

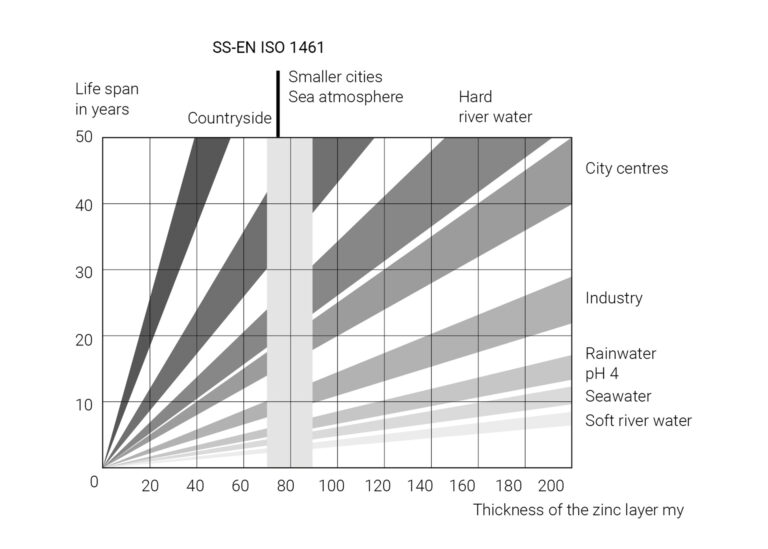

The diagram shows the average service life for different thicknesses of zinc in different environments.

Pickling

Stainless steel

During the welding and grinding of stainless steel objects, the surface is damaged. If these areas are not treated by pickling, there is a great risk for corrosive attack. To restore the surface and obtain satisfactory corrosion resistance, the product has to be pickled.

Aluminium

Aluminium grating is pickled to achieve a good surface finish.