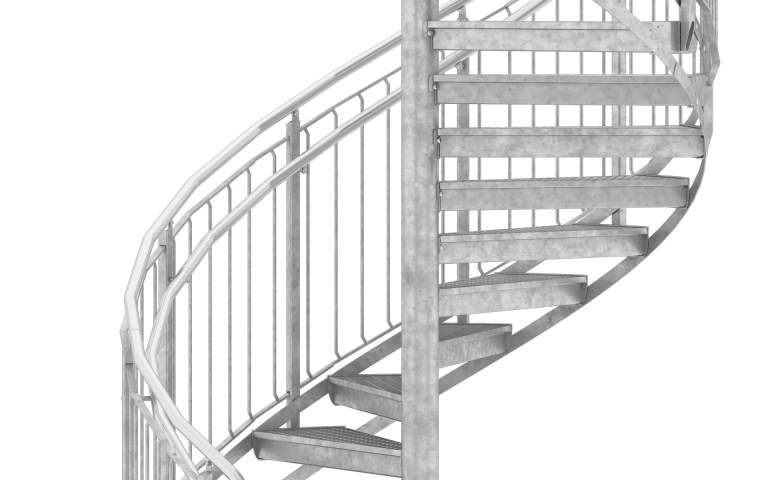

SPIRAL STAIRCASES, PLANNING AND DESIGN

With many years’ experience, we are happy to help you with guidance and advice during planning and design. On ordering, each spiral staircase is drawn up specially and the drawing is sent to the customer for approval prior to manufacturing.

Filtration

Railing infills

Additional information about our range of railing infills.

One U-baluster per step, mounted on the outside of the stair tread’s end.

A simpler form of child-proof railing with a hoop welded to a U-baluster. No opening in the railing is wider than 100 mm.

The railing infill comprises 25×8 mm flat-steel top and bottom rails. Round bars ø11 mm. Max. opening 100 mm.

1-4 intermediate rails made of 50×3 mm flat steel. An intermediate rail can be used on high industrial staircases.

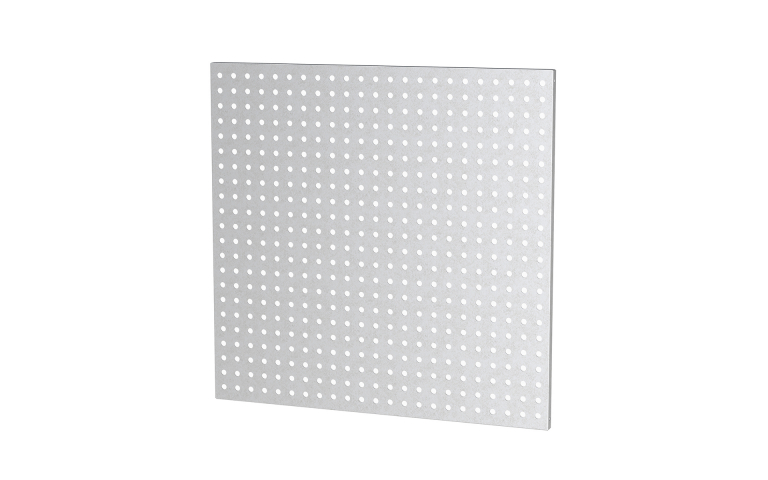

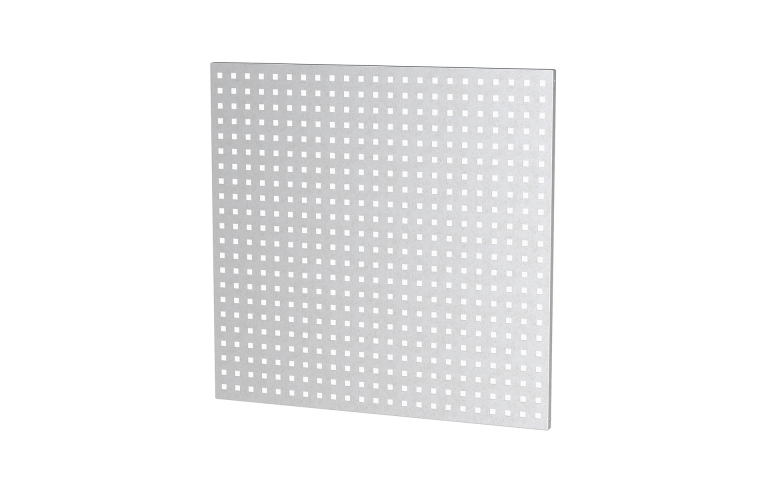

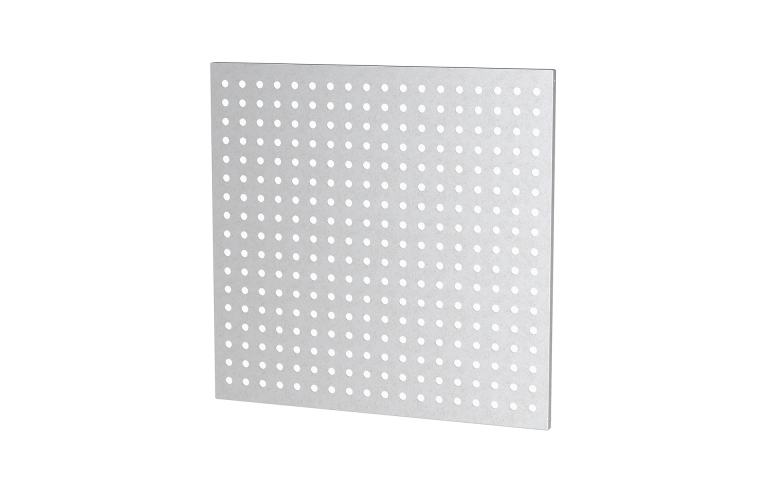

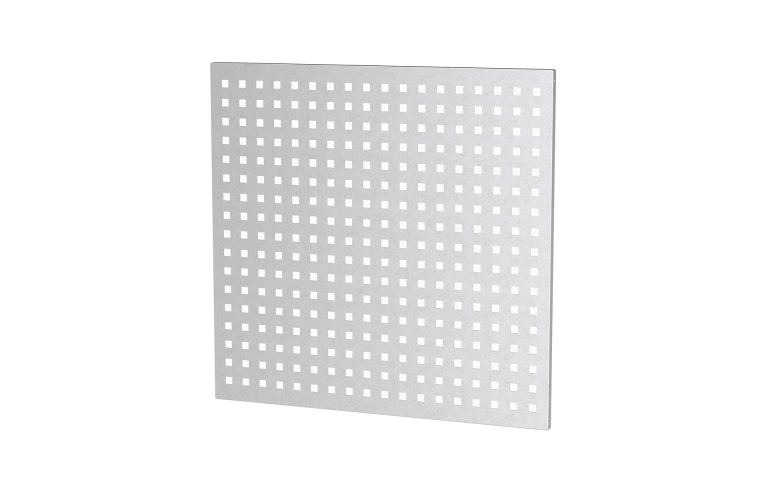

We offer perforated sheet metal with a choice of hole patterns as standard.

Our most common patterns:

- ø15, square pattern c/c 40

- 15×15, square pattern c/c 40

- ø20, square pattern c/c 50

- 20×20, square pattern c/c 50

- ø15, triangular pattern c/c 50

- ø20, triangular pattern c/c 60

Other options are available.

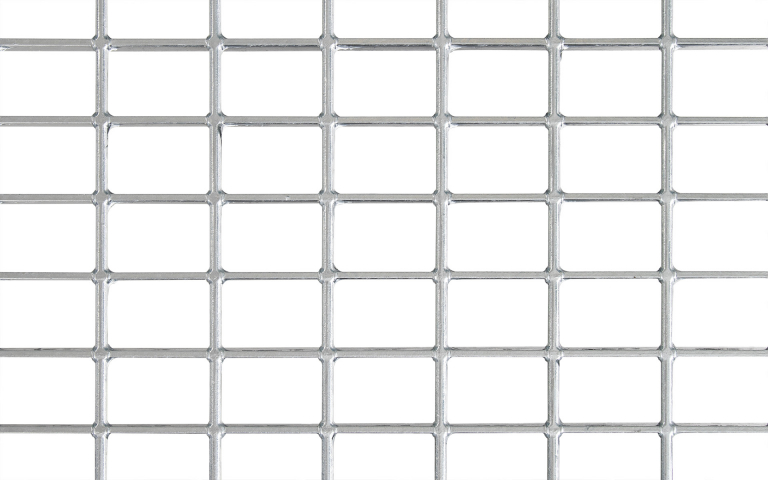

Woven wire mesh with standard 40×40 mm apertures. 30×30 mm apertures also available.

8 mm tempered laminated glass set in layers.

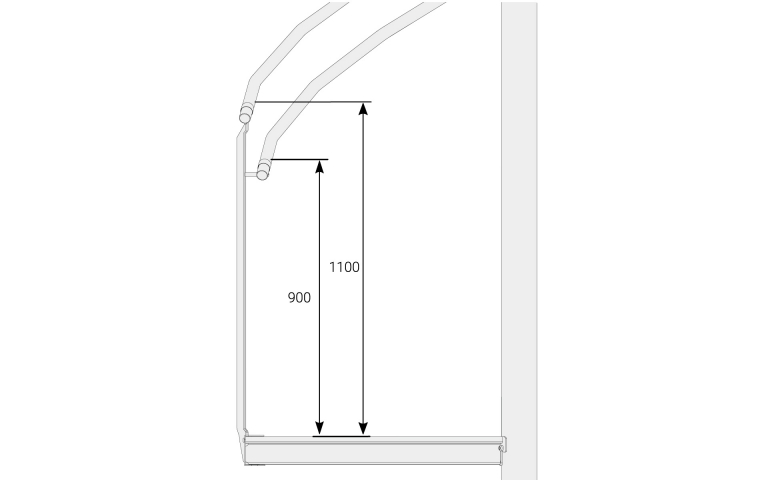

Height, railing

The height of the railing is 1100 mm at the nose of the step. Extra handrails are placed at an optional height inside the balusters, for example, 900 mm. The railing height of the landing is 1100 mm as standard.

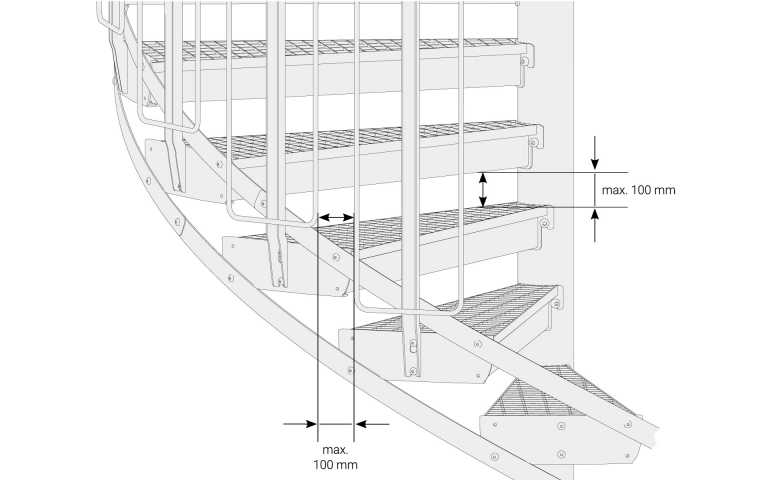

Childproof

Childproof means that none of the openings in the staircase are permitted to be larger than 100 mm up to a railing height of 800 mm.

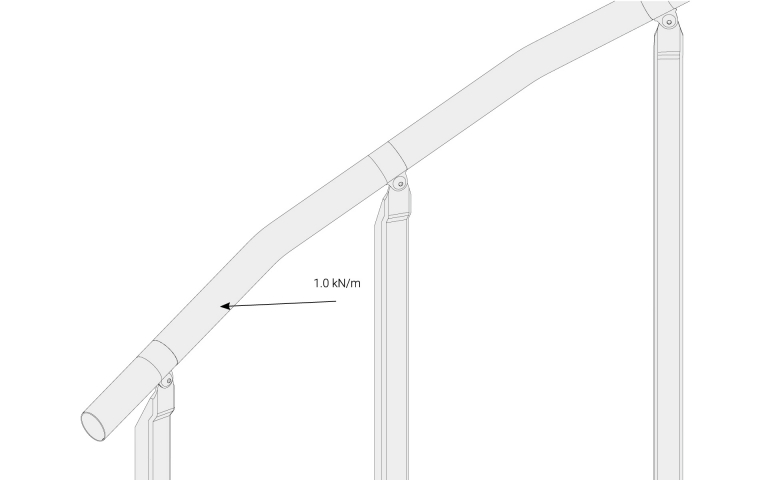

Handrail

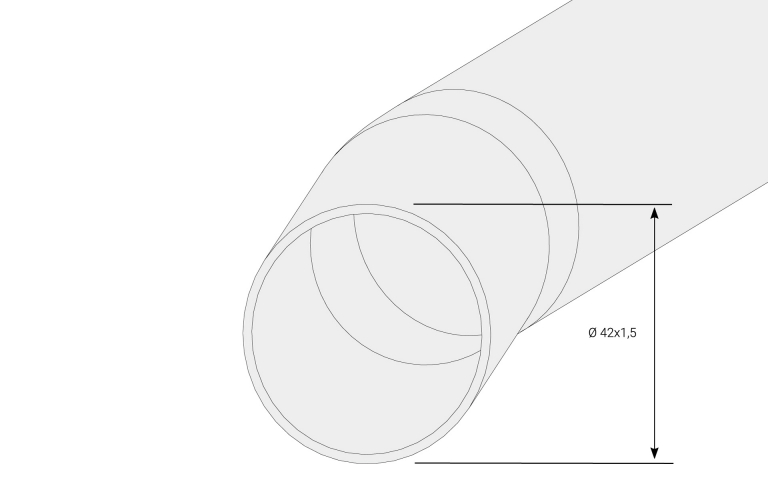

As standard, the handrail is manufactured in galvanized steel according to ZM310 with a diameter of ø 42 mm. For wood handrails, the handrail is ø 50 mm as standard.

Stair treads

Additional information about our range of treads.

Grating stair treads with 33×50 mm mesh width. Hot-dip galvanized finish.

We recommend 17×75 mm if a closer mesh width is required.

Tear plate treads with a hot-dip galvanized finish.

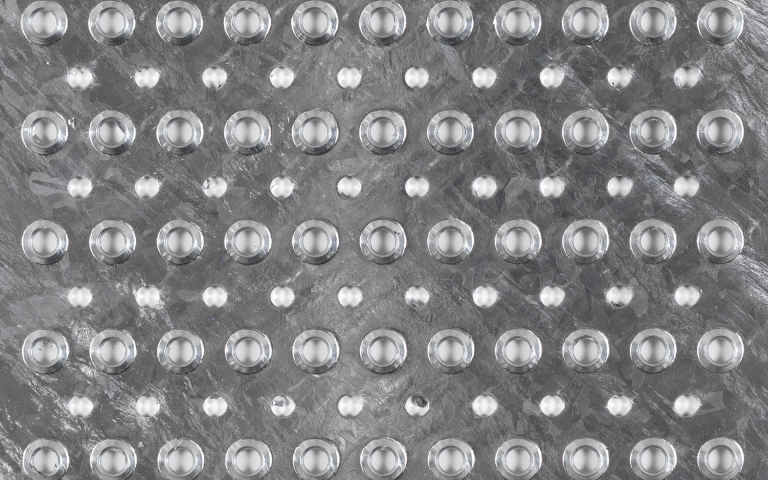

Hot-dip galvanized perforated plate stair tread – a good

alternative to grating if you are looking for a more solid

step surface. Hole pattern ø 10 mm with triangular division

30 mm. Half of the holes are collared in order to achieve the

best scraping effect.

Grey concrete stair treads. Thickness 50 mm. The tread surface is finely brushed. The other sides are smooth cast. If the staircase is outdoors, the tread surface is coarsely brushed. The concrete rests on a support frame of sheet metal profiles.

Terrazzo concrete stair treads. Thickness 40 mm. Comes with matt polished tread surface. The concrete rests on a support frame of sheet metal and profiles. This type of tread is suitable for outdoor use. Standard colours STT 1-102, 1-240, and 1-130. Other colours can also be offered as an option. Colour 1-171 is a contrasting colour used in contrast markings.

Stair treads shaped like a metal box for laying tiles. The standard depth of the metal box is 27 mm.

Stair treads that are to be carpeted come with a sheet metal tread designed for carpets. Stair nosing should be used if it is not possible to fold the carpet over the front edge.

Ash wood stair treads of solid, glued laminated timber, 30 mm. Coated with hardened lacquer as standard.

Birch wood stair treads of solid, glued laminated timber, 30 mm. Coated with hardened lacquer as standard.

Beech wood stair treads of solid, glued laminated timber, 30 mm. Coated with hardened lacquer as standard.

Oak wood stair treads of solid, glued laminated timber, 30 mm. Coated with hardened lacquer as standard.

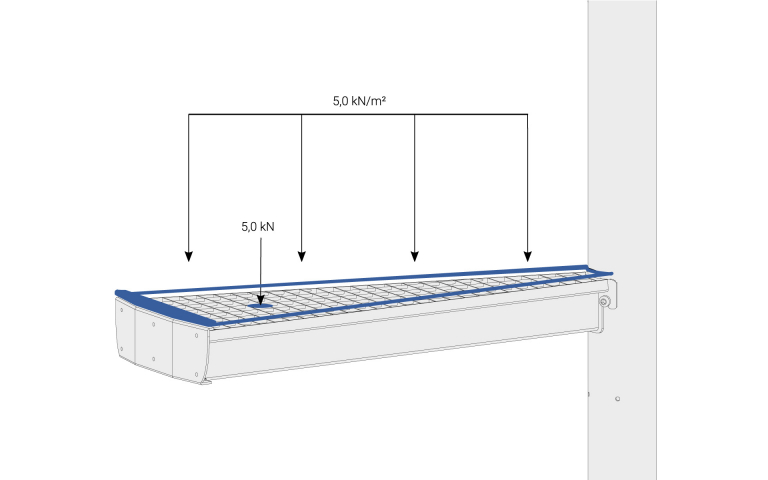

Load on tread

The stair treads are dimensioned for a distributed load of 5.0 kN/m² or a point load of 5.0 kN.

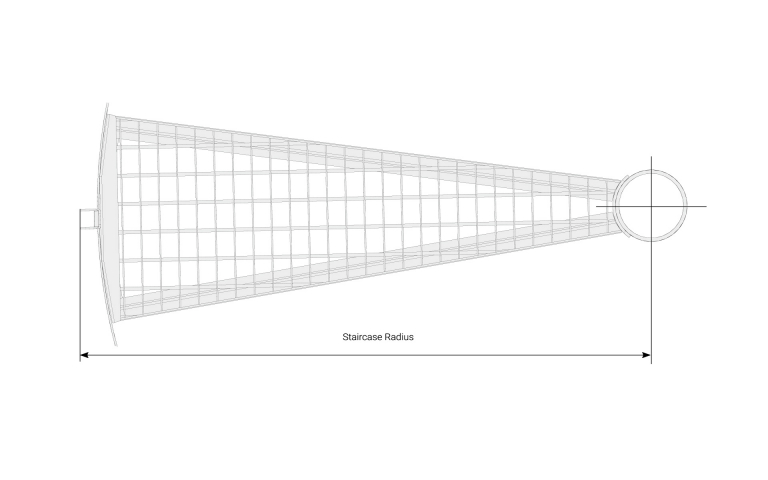

Staircase radius

The staircase radius is the dimension from the staircase’s centre to the outer edge of the handrail. Weland manufactures spiral staircases with a radius of 600 to 1500 mm. Within this range, there are standard radiuses on even decimeters.

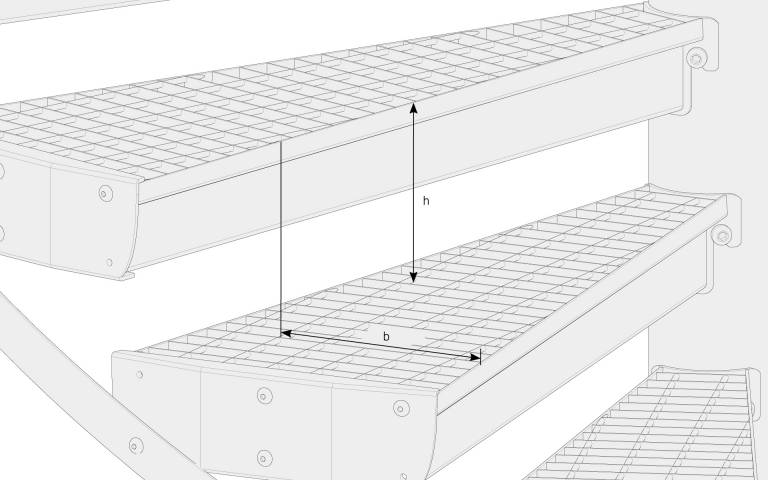

Rise

The rise should be chosen based on the given height between the landings. A suitable radius and the number of steps per revolution then determine the step rise.

The step rise should be between 160 and 220 mm. The lower the rise you choose, the deeper the step needs to be. The normal rise is about 170 to 180 mm.

The formula for the rise is 2 x h + w = 600- 630 mm.

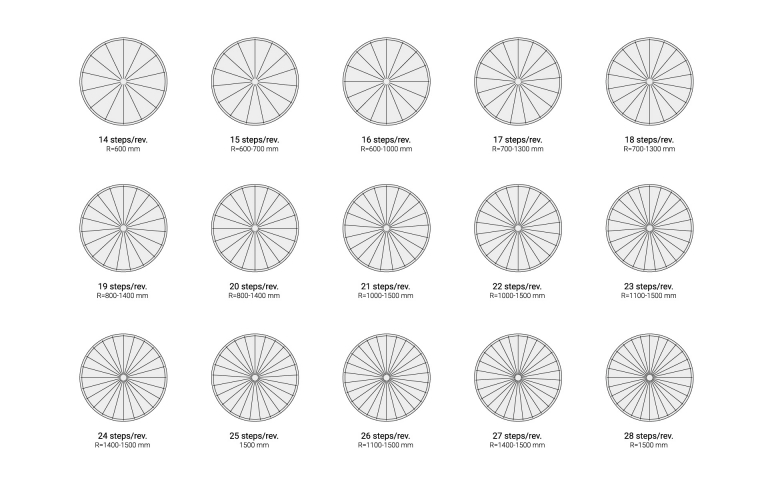

Number of steps per revolution

The step template on the right helps you plan the staircase solution and to determine the number of steps per revolution. The table below shows the tread depth along the path line for each radius and suitable riser heights.

You will find the step template at the bottom of this page alt. click here to go directly to our step template.

| Radius steps/revolution | Tread depth along path | Suitable riser |

|---|---|---|

| 600/14* | 157 | 200-220 |

| 600/15 | 147 | 200-220 |

| 600/16 | 137 | 200-220 |

| 700/15* | 188 | 200-220 |

| 700/16 | 177 | 200-220 |

| 700/17 | 166 | 200-220 |

| 700/18 | 157 | 200-220 |

| 800/16* | 216 | 180-210 |

| 800/17 | 203 | 180-210 |

| 800/18 | 192 | 190-220 |

| 800/19 | 182 | 190-220 |

| 800/20 | 173 | 190-220 |

| 900/16* | 255 | 175-200 |

| 900/17 | 240 | 175-200 |

| 900/18 | 227 | 175-200 |

| 900/19 | 215 | 180-210 |

| 900/20 | 204 | 180-210 |

| 900/21 | 194 | 180-210 |

| 1000/16 | 294 | 165-185 |

| 1000/17 | 277 | 165-185 |

| 1000/18* | 262 | 165-185 |

| 1000/19 | 248 | 175-200 |

| 1000/20 | 236 | 175-200 |

| 1000/21 | 224 | 180-210 |

| 1000/22 | 214 | 180-210 |

| 1000/23 | 205 | 180-210 |

| 1100/18* | 297 | 165-180 |

| 1100/19 | 281 | 165-180 |

| 1100/20 | 267 | 165-190 |

| 1100/21 | 254 | 170-200 |

| 1100/22 | 243 | 170-200 |

| 1100/23 | 232 | 170-200 |

| 1100/24 | 222 | 170-200 |

| 1200/17 | 351 | 155-190 |

| 1200/18 | 331 | 155-190 |

| 1200/19 | 314 | 155-190 |

| 1200/20* | 298 | 155-190 |

| 1200/21 | 284 | 155-190 |

| 1200/22 | 271 | 160-200 |

| 1200/23 | 259 | 170-200 |

| 1200/24 | 249 | 170-200 |

| 1300/18 | 366 | 155-180 |

| 1300/19 | 347 | 155-180 |

| 1300/20 | 330 | 155-180 |

| 1300/21 | 314 | 155-180 |

| 1300/22* | 300 | 155-190 |

| 1300/23 | 287 | 155-190 |

| 1300/24 | 275 | 155-190 |

| 1400/20 | 361 | 155-180 |

| 1400/21 | 344 | 155-180 |

| 1400/22 | 328 | 155-190 |

| 1400/23 | 314 | 155-190 |

| 1400/24* | 301 | 155-190 |

| 1400/25 | 289 | 155-190 |

| 1400/26 | 278 | 155-190 |

| 1500/22 | 357 | 150-180 |

| 1500/23 | 341 | 150-180 |

| 1500/24* | 327 | 150-180 |

| 1500/25 | 314 | 155-180 |

| 1500/26 | 302 | 155-180 |

| 1500/27 | 291 | 155-180 |

| 1500/28 | 280 | 155-180 |

* = Staircase that should be aimed for

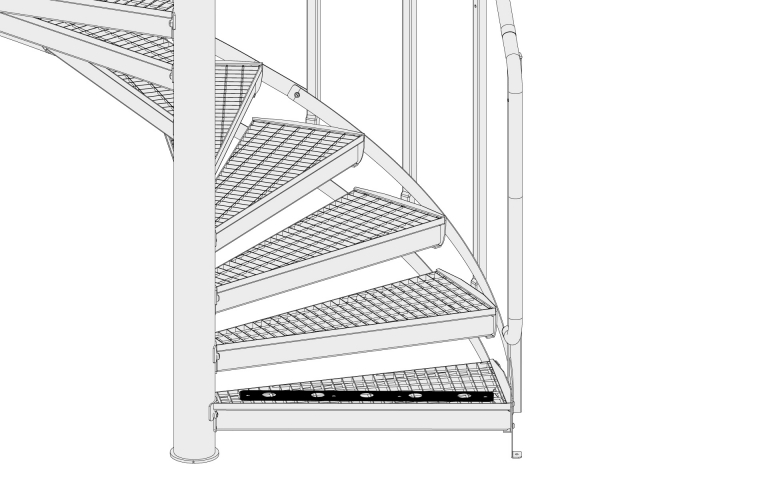

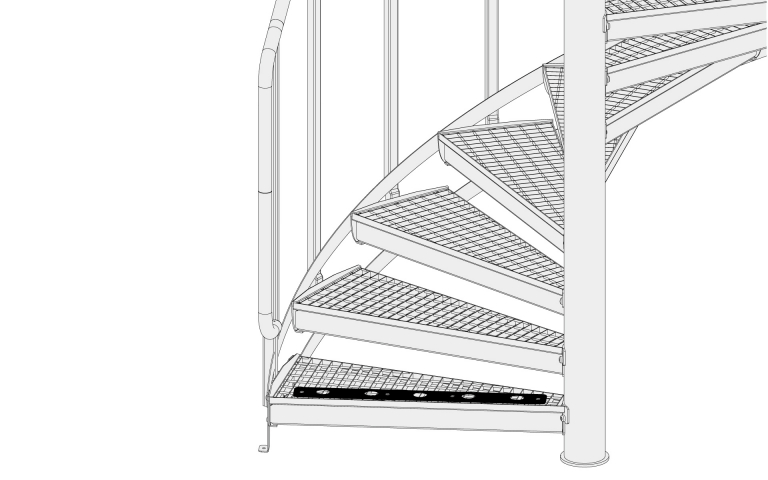

Right or left curved staircases

Weland spiral staircases are manufactured curved to the right or the left. Right curved staircase means that it curves to the right while ascending (centre tube to the right while ascending).

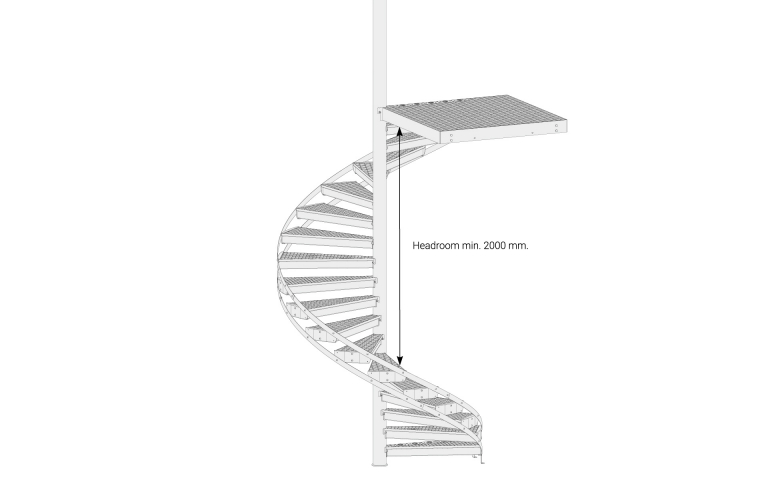

Headroom

The headroom on the stairs must not be less than 2000 mm. The height is measured between two points located directly below each other.

Measure from the top edge of the lower step’s nose to the lower edge of the landing’s (step) rear edge.

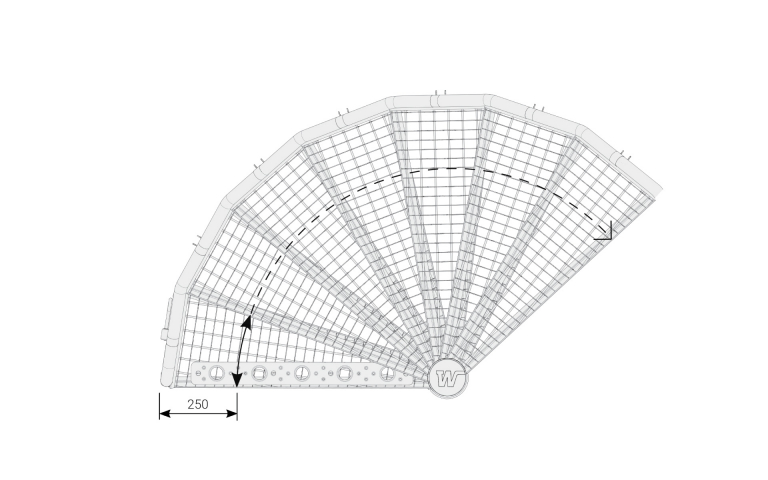

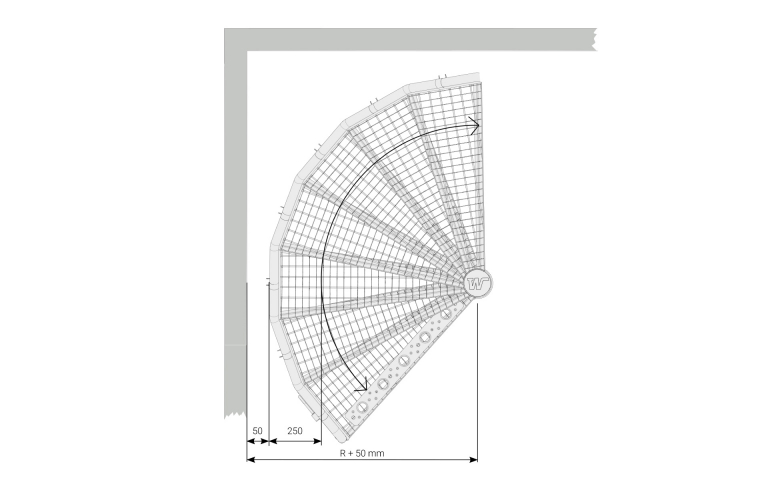

Distance to wall and tread depth

The spiral staircase’s external radius must be at least 50 mm from walls. The tread depth is calculated along an imaginary path 250 mm from the radius.

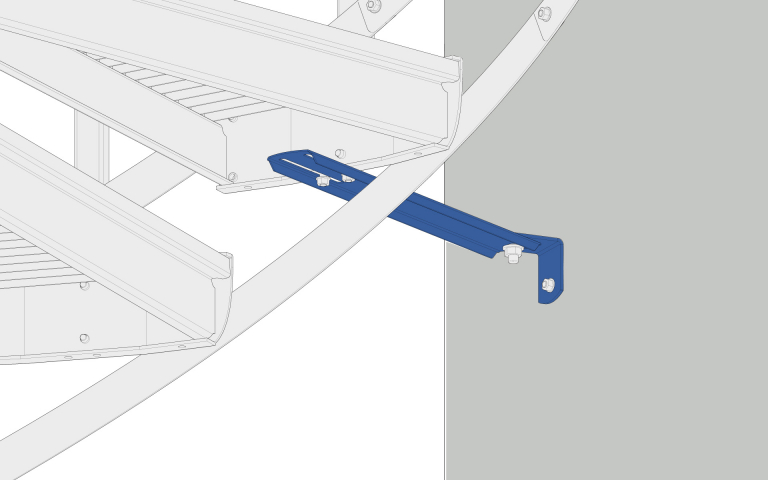

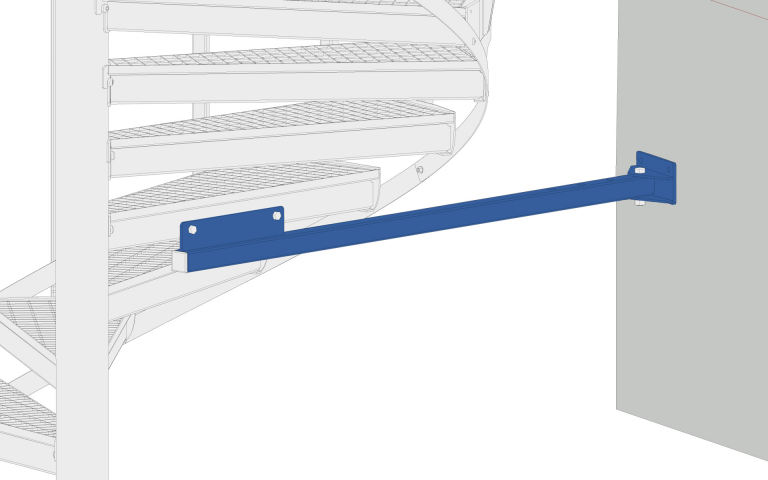

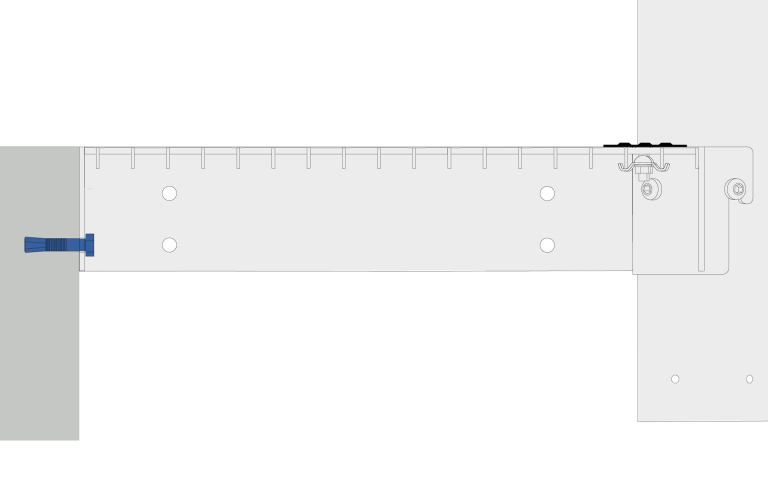

Stays

The spiral staircase must be fitted with stays every revolution (2.5 to 3 metres in height). This can be done using the square landing fixing. If the stairs have no square landing on each revolution, bracing must be fitted between the step and wall using custom stays.

If the staircase is to be braced to sandwich panels, we can help you in your planning and design with several smart solutions. Contact us.

Attachment of landings

Use suitable type of screw taking into consideration the materials at the attachment points.

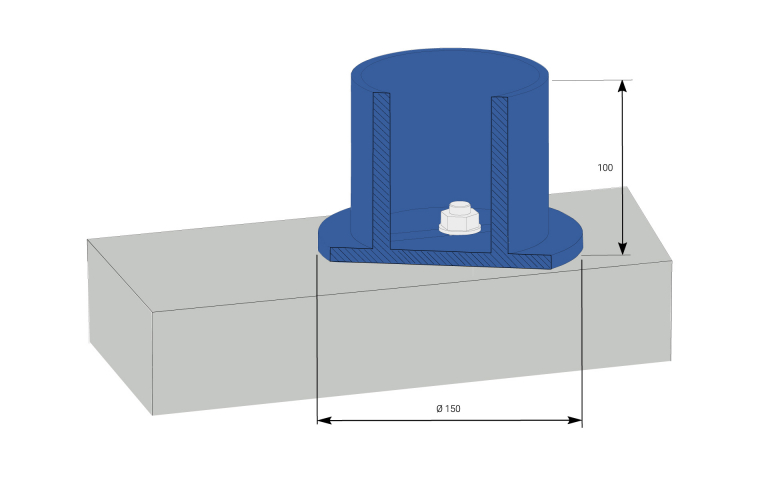

Attachment base plate

Use suitable type of screw taking into consideration the material at the attachment point.

A base must be cast to fasten spiral staircases when there is no existing platform. Wind strengths, etc. must be taken into consideration when designing this. Note that attachment at the first step must also be done.

Generally, the distance to the base plate from the wall must be at least the stair’s radius plus 50 mm.

Fire resistance rating R30

We also offer spiral staircases with fire resistance rating R30. Requests for specific sizing should be stated in the contract documents.