DESIGN

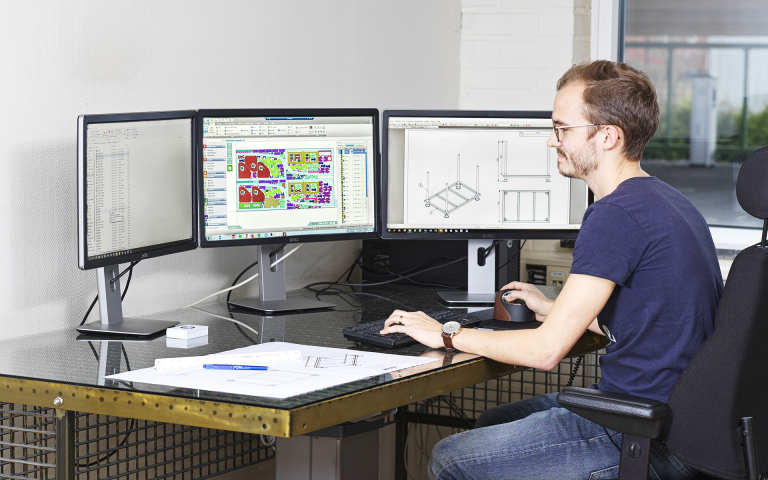

All programming of our laser machines is performed in our drawing office, where our personnel have many years of experience in laser programming.

Design

Our drawing office works with the most up-to-date CAD equipment, where, first and foremost, we use SolidWorks. We can assist with the preparation of drawings or accept finished drawings from you, along with a dwg or stp file. All programming of our laser machines is performed in our drawing office, where our personnel have many years of experience in laser programming. As a result, we are currently programming on average 50 new components per day, all year-round. This is also where we make adjustments to our own production, prepare material for components, and calculate cutting times.

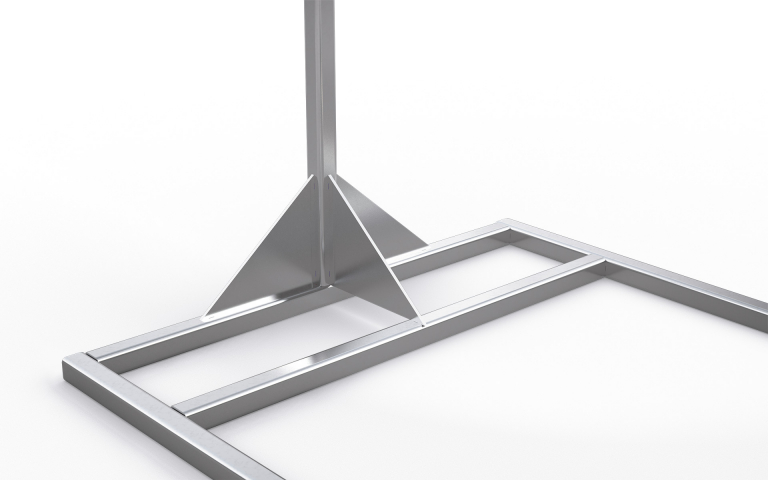

Tenoning

Already, while the parts are being laser cut, they can be prepared with tenons, mitres, notches and holes in the goods. This gives a perfect fit prior to welding without any need for expensive jigs. Tenoning facilitates the assembly and joining of the parts. You get a perfectly assembled product.

Tenoning is available for both plane laser cutting and tube laser cutting.

Minimisation of wastage

We work hard to use the sheet metal to the maximum, in other words, to have as little wastage/scrap as possible. Weland’s goal is always to be at the cutting edge of new technology. This also applies to our software. We have an advanced system for monitoring/reporting the consumption of materials. In this system, it is easy for us to follow the exact progress of a cutting plan, to see which parts are being cut. All material reporting is done automatically, which means that all of our material balances are always up-to-date and we can easily monitor how much waste is generated.

All stages of the production chain are subject to careful control and we work according to the ISO 9001 quality management system. We are also environmentally certified according to ISO 14001.